-

Posts

6,864 -

Joined

-

Last visited

-

Days Won

168

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by saddlebum

-

Assuming your talking about the type of coil spring that runs horizontal along the header and requires twisting to increase tension and not the stretch type springs which sit vertical at the each side of the door and unless you have an extra high door instead of the average 6'6" to 7' door some of the places that supply parts to the truck and trailer industry may have a spring that will suit your needs. The springs used for the box roll up doors are much the same you just need to match one up with your old spring. Though inside diameter and wire diameter are important because of the hubs at each end there is some room to play with the spring length as long as it fits it just changes the number twists you need to put into the spring to get the right tension, keeping in mind if the spring is much too short you may not get enough twists to cover the travel distance of the door although most garage doors travel about the same distance as a trailer door give or take a tad.

-

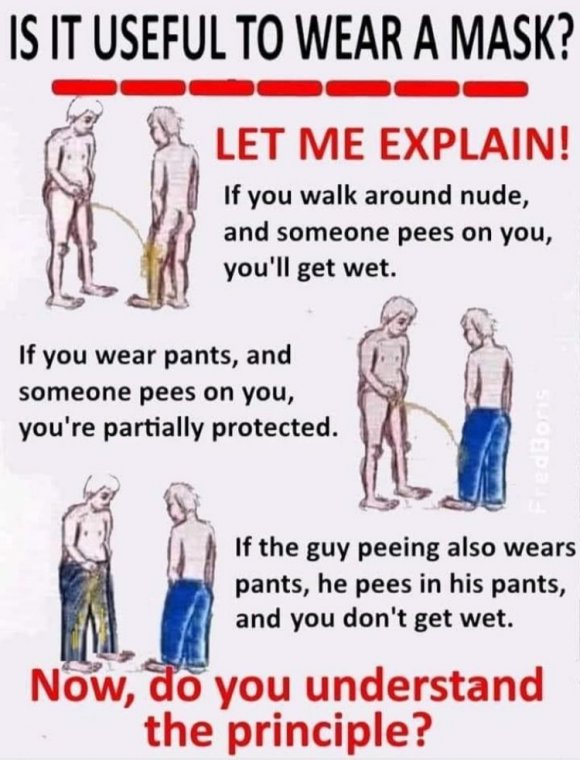

I don't know about that, wearing or not wearing a mask has not changed my financial situation at all. I am just as broke as I ever was.

-

Safety issue- ignition relay definitely saved my ignition switch

saddlebum replied to VentureFar's topic in Watering Hole

Most terminals are available for various wire sizes if increasing wire size is something you wanted to do. Alternatively if a wire is to big for the terminal you can get away with trimming a few strands to make it fit. Since wire resistance is based not just on the gauge of the wire but also on the accumulated length of the wire which increases with the length of the wire, trimming back 1/8" of an inch at the terminal, though not the best of choices is still an improvement over a lighter gauge wire. Ever notice how a power tool looses power when an extension cord is too long and the cord gets warm. yet you replace that cord with a much shorter cord of the same gauge the cord remains cool and the power tool is back to full power. The same occurs if you replace the cord with one of equal length but heavier gauge. Common Wire Gauges AWG wire size (solid) Diameter (inches) Resistance per 1000 ft (ohms) Resistance per 1000 m (ohms) 24 0.0201 25.67 84.2 22 0.0254 16.14 52.7 20 0.0320 10.15 33.2 18 0.0403 6.385 20.9 16 0.0508 4.016 13.2 14 0.0640 2.525 8.28 12 0.0808 1.588 5.21 10 0.1019 0.999 3.28 -

The mask stops the droplets / moisture vapor that carry the virus. Farts are usually dry not found in droplets, unless its a wet fart in which case (A) Oooo Boy and (B) wet farts do not generally pass through Fabric, just make you walk funny. 🥵

-

I could demonstrate in person if you provide enough beer but then at the end of the demo I would have to drive all the way home with wet pants.

-

But how many helping hands did it take to get him back up 😜 Well you know every group has someone who just can't help being a real photo ham.

-

For the best advice on trailering your bike visit the Harley forum. If they don't know ain't nobody knows.

-

Prayers sent. Very sorry to hear about their situation.

-

What to do after you decide to quit riding motorcycles?

saddlebum replied to M61A1MECH's topic in Watering Hole

-

Is this how I drain my oil?

saddlebum replied to YoungWayne's topic in Venture and Venture Royale Tech Talk ('83 - '93)

The impact tool Skydoc mentions is a very useful tool to have on hand not just for the drain plug. I have one in my box at work, one in my mobile tool box and 2 in my home garage tool box. The second one of the two at home I welded on to it the handle I cut from a worn out adjustable wrench. It keeps it from twisting in my hand when I use it with a heavy mallet to break loose heavy bolts up to 5/8 " and have broken loose bolts a breaker bar would not budge. When putting the valve covers back on 1st check to be sure none of the rubber plugs that sit on top of the cams came out while removing the valve covers and be careful not to do the same as you put the valve covers back in place. I once discovered one in the bottom of an engine while replacing the clutch. Oil pressure can escape through the holes these plugs fill and they are held in place by little nubs molded into the underside of the valve cover. -

Safety issue- ignition relay definitely saved my ignition switch

saddlebum replied to VentureFar's topic in Watering Hole

This could hold true if more load was added to the circuit than it was originally designed to carry but even in a perfectly sized circuit, if connectors loosen up which is common with round eyelet terminals, were screws sometimes vibrate loose and extremely common with push on terminal which tend loose their tension and become loose heat is created. The flat 1/4" wide blade type push on terminals, are specially bad for this. As their grip loosens resistance increases causing heat which further loosens the terminals grip. Eventually this cycle continues to were so much heat is created that the plastic plug these often sit in melt and as this heat transfers back along the wire the insulation melts barring the wire and this now bared wire can either burn through the insulation on other wires or contact ground creating a dead short, were if your lucky the fuse will blow but if it fails to blow because it is too large, the problem can continue back along the harness damaging additional wires either within the circuit itself or melting into wires that run along side it as in a harness. In this type of circumstance increasing wire and fuse size would not help and could actually be a problem since the increased fuse size would not blow as readily and the increased wire size instead of burning through would simply help to spread the issue further as described in the previous sentence. I cannot even count the number of times I have seen customers increase wire and fuse size from the fuse box to some add on device only to have the wire that supplied the fuse or even the fuse box itself burn up because someone thought simply increasing the fuse size and the size of the wire from the fuse to the add on device was good enough. This is were a really is a smart move as long as it is wired properly. By these I mean you can use the original wire to activate the relay but the the power going through the load terminals to the load should come directly from the battery or equivalent through a proper sized fuse and wire size to meet the load requirements to the relay (usually terminal 30 ) and then from the relay ( usually terminal 87 ) to the load. With regards to the 30/40 amp rating. This is normally on a 5 terminal relay were terminal 87 is normally open and terminal 87a is normally closed. Terminal 87 is rated at 40 amps were terminal 87a is rated at 30 amps. -

Most dyes for leak detection are safe We use at it at work all the time for oil, AC and diesel fuel leaks. just make sure the dye you use is for the type of fluid your dealing with and yes most are very safe to use. Personally I have not come across one that is not ( and we use them frequently at work )as long as you use it properly. Example do not over use and do not use dye intended for AC systems in lubrication systems or visa versa.

-

Is this how I drain my oil?

saddlebum replied to YoungWayne's topic in Venture and Venture Royale Tech Talk ('83 - '93)

There is also a screw at the bottom of the middle gear cover with a copper washer on it that will allow you to drain almost an extra 1/4 cup of oil if you remove it with the bike on the side stand. With regards to the main plug. try giving it a few solid raps up against the case with a hammer. This often helps to break it loose. Just don't drive right up through the case. -

I agree, The way the chap did it in the video left me thinking the wheel could still slide side to side within the confines of the strap.

-

Prayer sent along with my best wishes for both of you.

-

Safety issue- ignition relay definitely saved my ignition switch

saddlebum replied to VentureFar's topic in Watering Hole

He mistook you for his long lost twin brother by the same name. They had a lot in common. -

Safety issue- ignition relay definitely saved my ignition switch

saddlebum replied to VentureFar's topic in Watering Hole

Go for it. you can try but if she is like my wife she will just say then the rest of the world is wrong too. -

Safety issue- ignition relay definitely saved my ignition switch

saddlebum replied to VentureFar's topic in Watering Hole

@RDawsonis correct a relay is not a circuit breaker. The amp rating on a relay only indicates the highest load a relay can carry not the protection given to the circuit, therefore it does not matter how thin the wire is as long as the wire and fuse or breaker are the correct size for the load on the circuit. Any size relay can be used as long as the amp capacity of the relay is larger than the circuit load. So if the circuit load is designed and fused for 20 amps any relay rated larger than twenty amps is OK to use whether it be a 30 amp Relay or 75 amp Relay. Going to a heavier gauge wire and corresponding fuse is only required if the load on the circuit is more than what the existing size of wire and fuse combination in the circuit is able to carry -

Water getting in gas tank through vent hose?

saddlebum replied to GrahamLFCkeeper's topic in Watering Hole

I have posted this before but will again since it may be useful to some. It lists ethanol free gasoline locations. https://www.pure-gas.org/about https://www.pure-gas.org/chart Interesting FAQ from the above website; Can I test gas myself to see if it contains ethanol? Yes, and it's quite easy to do. Inexpensive fuel-testing kits are widely available, or you can just do it yourself: Pour a small amount of water into a narrow jar (an olive jar works great) and mark the water level with a Sharpie. Add the fuel to around a 10:1 fuel:water ratio. Shake well, let settle for a few minutes. See if the water level has risen above the mark. If it has risen, it has combined with ethanol from the fuel.