circa1968

Expired Membership-

Posts

405 -

Joined

-

Last visited

-

Days Won

19

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by circa1968

-

Rear Diff oil, should it look like this?

circa1968 replied to circa1968's topic in Royal Star Venture Tech Talk ('99 - '13)

@djh3 @saddlebum @Marcarl Thanks guys! I will report back in a few hundred miles. In the mean time, I looked up the breather and its only ~$14 on partzilla, so maybe worthwhile just changing it as a precaution anyways. But its a perfectly round and smooth chrome knob. Any idea how one goes about getting that sucker off and a new one back on? More on the re-install, I can gorilla the old one off, I'm sure. -

@BlueSkyYou were right! I'm extremely grateful and appreciate you making this suggestion. All but two valves were out of spec and those two were right at the lower limit. My thinnest gauge is .03 and It would not fit under two of them. I could spin the bucket easily with my fingers, so I think it was not yet at zero though. I bought the needed shims at my local dealer and the guy who helped me said these bikes were known for needing an adjustment within 6k miles of new and then ~ every 10k after. I've now successfully completed my first valve clearance adjustment job and one step closer to getting my Youtube Certified patch! LOL Thanks again for that recommendation!

-

Rear Diff oil, should it look like this?

circa1968 replied to circa1968's topic in Royal Star Venture Tech Talk ('99 - '13)

@Marcarl @saddlebum I just renewed my membership last month and you guys are making me feel guilty as I've already gotten more than my $12 worth here! Thank you! The knowledge...I appreciate you guys! -

Rear Diff oil, should it look like this?

circa1968 replied to circa1968's topic in Royal Star Venture Tech Talk ('99 - '13)

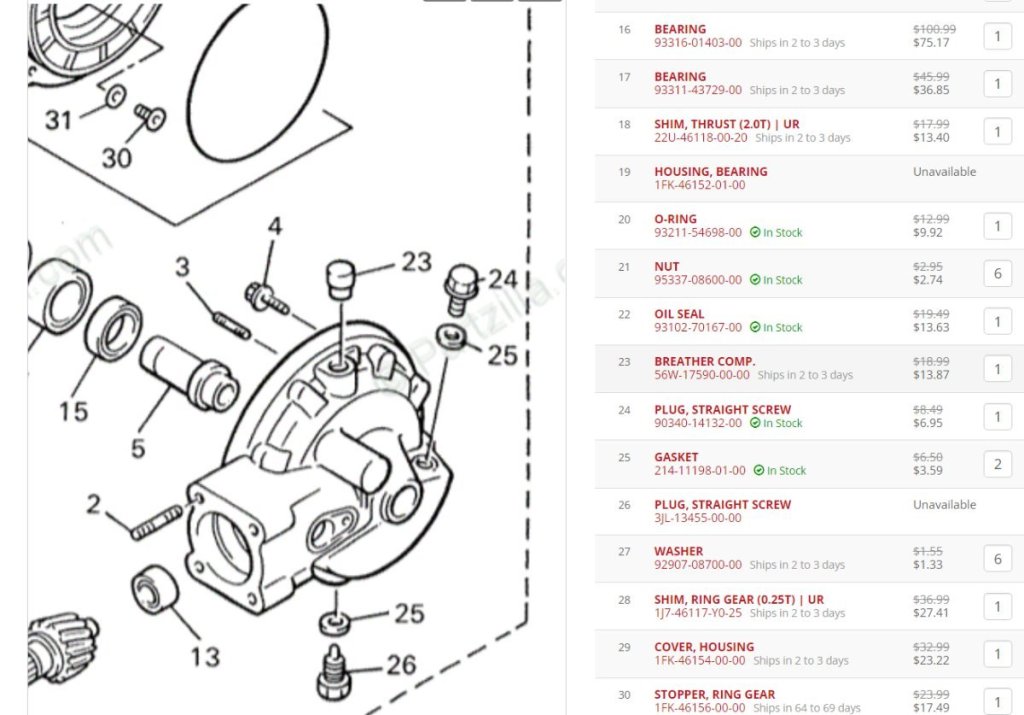

Hey Guys, While I never underestimate my ability to do stupid shtuff, I have always been aware of the damage high pressure washers can do and know to be super careful. I was just out looking @ my Venture to see how/where I could have gotten water into the rear diff while washing. I'm scratching my head, because even if I wanted to, it sure looks like I would have to try pretty hard to even hit any part of the rear diff directly with a blast of high pressure water. So, I went to the exploded view dwg on partzilla (attached) to see where the vulnerable areas are and now have a couple more questions. 1) What is item #23, the 'breather'? Is that a possible point for water entry? 2) I have never pulled the rear wheel myself, so unsure of what that entails, but I've had a small local independent shop do two rear tire changes for me. Not sure how to ask this, but is there an opportunity to not get something put back together correctly that would create an opening for water to get in? Perhaps via the axle or leaving out an o-ring, seal or possibly pinching one of those? Other than doing another gear oil change in a few hundred miles to see how it looks, I won't be digging into fixing any potential problems here but will leave that to my local dealer techs, if need be. Just trying to educate myself on possible causes so as to have a semi-intelligent conversation with them when that time comes. Thanks, so appreciative for all the knowledge here. -

Rear Diff oil, should it look like this?

circa1968 replied to circa1968's topic in Royal Star Venture Tech Talk ('99 - '13)

Ah, that makes sense. I'm planning to take it to the local dealer in January to get it ready for some 2022 travels. I have a list of things for them to look at/do, so will add that to the list. It hasn't seen much of any rain at all, just a couple of light rains (I was lucky), but I have been to the carwash with it a couple of times. I'm always careful to stay back quite a ways with the pressure hose, but perhaps not careful enough. -

No Main/Ignition Power

circa1968 replied to Du-Rron's topic in Royal Star Venture Tech Talk ('99 - '13)

According to the article, it came to a head late last year, around October IIRC, that's when it started being fully enforced. So, I would imagine initially it didn't make a huge impact while things were still somewhat shut down or just coming back online. But now that more of the world is back to being open for business, the logjam built up pretty quickly. Another CA specific issue that relates to all of this is how independent contractors are no longer allowed in CA. So a trucking company has to hire drivers on as employees, paying all the employment taxes, rather than simply paying them a straight rate as independent contractors. Companies did not want the extra employees or taxes & regulations which go with them, so let go a bunch of drivers who were previously independent contractors. This is a very tough state to do business in if you are a small business. It is that way by design, the big players own our legislature and pay for legislation that makes it near impossible for small operators to compete. All in the name of social justice, environment, equality, etc. I deal with it in my personal business and it is brutal. -

No Main/Ignition Power

circa1968 replied to Du-Rron's topic in Royal Star Venture Tech Talk ('99 - '13)

Which btw, has nothing to do with Covid or a shortage of truck drivers, as has been reported. Sorry to hijack and take this way off topic, but the reason for the logjam goes back to last year when CA implemented new truck emission rules that prevents any truck older than 3 years old (or has had its exhaust emissions upgraded) from entering CA to pick up cargo. I've ridden my Venture from San Jose to St. Louis twice this year. 1st time in the spring on the southern route across hiway 40 and 2nd time across hiway 70. What I can guarantee you is there is no shortage of trucks or drivers. On hiway 40, if I ever went 2 minutes without passing a truck, it was a rare event. It was non-stop trucks. And I saw numerous mile long trains hauling cargo boxes on each of those trips. With only CA-approved trucks allowed to enter the ports, they are having to load up, drive to the state line, unload & return empty to repeat, so at best 50% utilization of those trucks. So let's say 50% of the trucks in the country can't enter CA & then you only get 50% utilization from them. That gives you 25% of available trucking capacity for clearing the docks and when there's no more room on the docks for cargo, you get a logjam of ships waiting to enter port. This is 100% a self-inflicted wound from our tyrannical CA gov't. My apologies to the rest of the country, but I do not vote for any of these clowns. You can read more about it here: The California Version of The Green New Deal and an October 16, 2020, EPA Settlement With Transportation is What's Creating The Container Shipping Backlog - Working CA Ports 24/7 Will Not Help, Here's Why - The Last Refuge (theconservativetreehouse.com) -

Rear Diff oil, should it look like this?

circa1968 replied to circa1968's topic in Royal Star Venture Tech Talk ('99 - '13)

Thanks Guys! No sign of metal shavings. Agree it was cheap & easy enough to do that I will change it again in short order to see how it looks and go from there. -

This is my 1st time changing the rear diff oil. I had a local shop change it in the spring before a big trip and they said it was 'very nasty'. I just assumed the PO had not changed it in a while. So, after 8-9 months and ~11k miles, is this normal? Or is there something else going on I need to be concerned with? Oh, and the smell! It was nearly vomit inducing.

-

Hi @BuddyRich, I would be interested in a set. Any pictures?

-

Keep the memories forever and let the bike go, that's what I would do. But, to be honest I'm not the most sentimental person when it comes to things & objects after watching one of my brothers lose everything in a home fire some years back. It was a custom built log home, that he spent 7 years building, a magnificent place, even featured in a log home magazine once. It was a complete and total loss, including everything inside, literally a pile of ash. Well, almost everything. It still gives me chills - one photo album survived, with photo's of the house being built. All of us pitched in during the construction years, but Dad spent a lot of time there. Seeing slightly charred photos of Dad helping place the last log was a real tear jerker for all of us, he had passed away almost exactly 1 year prior to the fire. If I recall correctly it was exactly 1 year + one week. Don't quite know what to make of those sorta occurrences in life, but to me the lesson was our things can be gone in an instant, but our memories of good times with the people in our lives are really our most valuable possessions. Put it on craigslist, tell your story and you will very likely find someone who's excited to get the bike, restore it and make their own memories with it. I'm willing to bet at the end of the day, you'll feel a great sense of happiness sending it off to its new home and new family.

-

1967 Yamaha big bear YM2C

circa1968 replied to circa1968's topic in Links to Classifieds, Craigslist, Ebay, Sales, Etc.

Hey, its a bargain compared to this: https://sfbay.craigslist.org/eby/mcy/d/stockton-1947-indian-chief/7401430116.html Yeah, @Condor, I hear you. I would never pay $8500 for a pretty thing to just look at it. I'd rather have that bike beat up & tired for $500 and ride/wrench on it to my heart's content. Around here, there are too many people with stupid amounts of money, who like to buy pretty things to show off. It may take a while, but he'll probably get pretty close to his asking. I'm seeing running '80's japanese bikes go for $3-4k around here now, not in any kind of restored or show condition. -

Yep, stuck in my head now...that frosty mug taste! I still remember when my parents would say let's go into town and get some A&W root beer floats, we were in heaven. How times have changed.

-

I wear a full-face helmet with the visor in the up position, unless its raining, and I just crank it up to where it sounds good to me. At freeway speeds, that's usually ~17-19 with the auto speed adjust set to '5' This is an interesting option too: https://domiomotorsports.com/motorsports/ You will obviously need to be set up for BT streaming though.

-

Thanks for that @BlueSky! I think I can handle that procedure, these bikes seem pretty easy to work on. Will have to do some research on where to find shims, if needed though, before I dig into it.

-

I picked this up back in August, literally @ 9PM the night before leaving on a month-long road trip, because why not... Was looking for something smaller, a project (but not too complicated) and on a reasonable budget as a complement to my Venture for easy daily riding and this sweet girl came along. She has only 7700 miles on her and lot's of garage sit time (hadn't run in over 10 years) - which of course meant gunked up carbs, dried out rubber bits and rusty tank. Thanks to all you awesome folks here and the ton I've learned from you over the last year I, perhaps foolishly, had all the confidence to take this one on. After returning from my trip, I pulled the plugs and soaked the cylinders in Seafoam deep creep for 48 hours, changed the oil, new battery and lit her up with some starter fluid. She's alive! Next step, pulled the carbs. They weren't in as bad of shape as I expected, but bad enough. Ordered a K&L rebuild kit, along with new boots on both sides. The petcock is vacuum operated and all the bits inside were dried out as well, so those have been replaced with new. I did the drywall screws in the tank thing and let the rust rain out, then did a degrease, followed by the POR acid treatment, then POR-15 coating. Carbs are clean with new float valves, pilot screws and rubber bits. She runs, she purrs like a kitten! Actually, the carbs need a little fine tuning on the pilot screws and sync, but other than that, I was able to ride it around the neighborhood this evening. OMG, what a hoot! This thing has some punch. Oh, while I was waiting for all the bits & pieces to arrive, I painted the engine black. The engine was painted gold from the factory but it was badly faded and splotchy and I just had to knock a little bit of that '80's look off of it. Overall, the bike is very clean but the paint is not as good as it looks in this photo, it is a bit worn and beat, but still acceptable. I'm debating whether to keep it looking as it sits now or make it a longer term project to move it towards something more sporty looking. In the mean time, I will be overhauling the brakes and other various little things to make her truly road ready, but dang, this is fun!

-

Yeah, becoming more than obvious they don't want to even make 50 of them as they will not respond to my emails asking for a price quote.

-

So, before my spring trip, I did a “practice” replacement to see what was needed. Going from memory: 5mm Allen to remove the side covers Phillips to remove the center cover 12mm socket to remove the pump Plier/needle nose to loosen the hose clamps. I will take a look @ the exploded view deg later, to make sure I’m not forgetting anything, but it is not complicated at all. The worst part was dealing with the various wiring clamps/ties under the side cover. That and that darn screw for the center cover which is always hard for me to get back into place.

-

Glad you had a great trip and made it home safely. I was going over Rabbit Ear Pass on Sept 8th, having just come across hiway 14 from Fort Collins! Absolutely beautiful area. I carried a spare fuel pump with me on my trip (5,500 miles over a month), along with the couple of tools necessary to change it out, if need be. A lot of things could go wrong, but I figured if the fuel pump went out, its one problem I could easily fix anywhere, myself and it doesn't take up much storage space. If the points go out, I'll swap in the spare, replace the points when I get home and then still have a spare to carry with me. My spare is a very clean, used pump purchased off of ebay for $30. The same pump was used on other Yamaha Star models, so not hard to find used on ebay. Hope you are back up and running soon!

-

What he said! But I'm pretty sure the lights, etc would still work if the kickstand was down, while in gear. Same as if the kill switch was open. It just wouldn't turnover.

-

They did not. I asked them to quote chrome & powder coated black, but never heard back. I've been on the road since then, so I will follow up to see if they will provide a quote.

-

See the left side of the diagram for the color code/chart, but yes, Brown/Blue. How certain are you that the battery is good? I could be off base on this one but possible that it has enough juice for the stereo, but not for the rest of the stuff. The odometer not working is odd as that is fused before the main switch. That's what has me wondering about the battery.

-

That was my first thought too, but I confirmed on my bike that all the other stuff, lights, etc would still work. But still worth checking.

-

Couple of questions: 1) Does the odometer work when you turn the ignition to on? 2) Do the blinkers and/or horn work? Here's a link to the electrical diagram: https://www.venturerider.org/wiring/99-09 Yamaha Royal Star Venture Wiring Diagram Rev B.pdf Lot's of possibilities, but coming off the ignition switch, the stereo and aux power are on their own circuit, so sorta good news there in that hopefully not a bad main switch. The odometer is fused directly off the main fuse and should be working. The blinkers and horn, based on your symptoms are most likely not working. You may have a bad main switch or a problem with the wiring coming off of it, either @ a connector or broken wire itself.