-

Posts

2,036 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Gallery

Events

Store

Everything posted by Patch

-

That would be correct. You are tuning one jug at a time each tune effect the response it actually is caused by firing order. Just some back round: This has to do with lever on the crank, when 1 is more efficient then 2 causes some drag, tune 2 again and 3 causes the more drag, then 4 is draging 1 and you just repeat till the effect on the pilot shows a balance or no noticeable change; then you can turn in or out 1/4 turn on all 4! Then reset Idle Remember these efforts are not your riding power they just bridge till you hammer down;) Patch

-

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Yes really is a chase. So you caught on to the brown, I was using my xvz sheets, figured I was off. So my sheets show brown also ties the Eand, so what I would do is check continuity on the wire coming up from the thermo sending switch to the end where it connects to the dash or the to the temp gauge! That should be near 0 accounting for age of wiring. Just rule it out. Thee light of course you know will glow brighter with rpm the gauge is well... The fuel gauge is G/W so again lets isolate that one wire measure end to end. Then we'll see from there -

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

can u give me the voltage reading on both sides of fuse 4 pls. and battery to compare, locking for loss Here is the 83 wiring diagram the brown is of inerest Can you tell us what if anything was damaged after the fall anything at all? http://www.venturerider.org/wiring/83%20Yamaha%20Venture%20TK%20Wiring%20Diagram%20Rev%20C.pdf -

CLASS System ON while engine is running

Patch replied to rrod1393's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I get your point and I don't want to turn the thread around. These bikes are old, the coolant was obviously left to long and therefore some corrosion is visible. What isn't visible is or should be the concern! Another point and we have seen this here some time ago; these bikes are designed for the long hauls, way out there, and the Bar's I mentioned is preventative as much as potentially plugging a minor something after the corrosion is dissolved!! Have a safe season Patch -

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Well you must have answered the problem through the question. What is the common link? sorry I should know, what year is the bike? And did you put that dash through the dishwasher man? That is the cleanest old dash I have ever... -

One thing you can try is, use your enricher just a crack open then try your quick deceleration. If it helps then you know plus or minus a 1/4 turn at a time. Remember compression is the key to complete combustion, you should know what it is and budget or tune accordingly. Patch

-

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

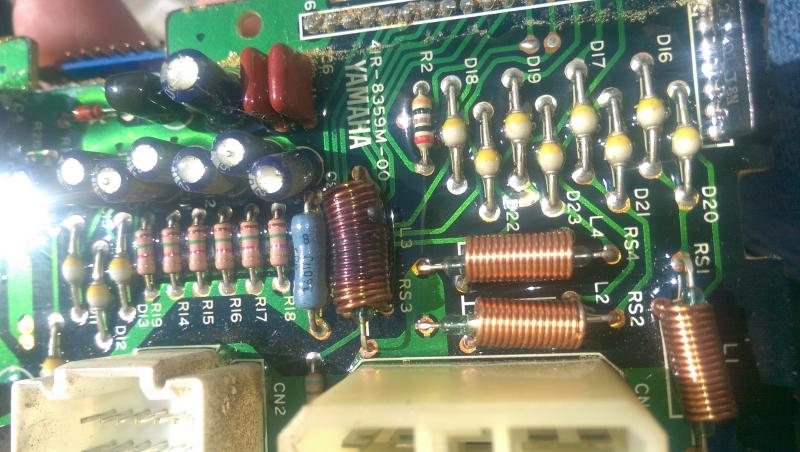

I found the old post. Looks like I had more than I remembered electrical issues..Hmm Anyways it look the the burnt coil you see in one of the pics controls the brake light.. Still worth a look see.. -

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

Looking through the manual page 7-84 and 7-81&82 open the back of the cluster and look at the circuit board is it clean? If not give it a cleaning with brake cleaner or whatever you have. Also look for what shows in the pic below.... Its been a while but I think that was my problem?? You could also check for power G/W wire at the other end (sender) 44 ohms full tank 1/2= 160-180 empty 273 ohms -

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I remember having an issue with my dash I am going to look through my notes? Did you open the cluster? Did you look at the circuit board? Seems to me on mine that is where I found the problem?? Patch -

CLASS System ON while engine is running

Patch replied to rrod1393's topic in Venture and Venture Royale Tech Talk ('83 - '93)

That is incorrect, the product is made to work throughout the system! This was a standard process for aluminum engines, designed to plug minor leaks only! Patch -

CLASS System ON while engine is running

Patch replied to rrod1393's topic in Venture and Venture Royale Tech Talk ('83 - '93)

No. If this is a new to you bike, I recommend that you flush the coolant system, with a radiator flush. Then rinse with fresh water or as recommend on the label. It does happen that old bikes will spring leaks, so its better to do the above, then add a leak preventer and lube to the system after flush and rinse if required! Note there are drain plugs in the heads, refer to your manual. Regarding the plugs, I wasn't very clear actually mixed a couple of threads up. The wiring harness has many plug connections, which can cause as many problems. So I am suggesting that you get a jump on it by opening the connections cleaning then.... as mentioned Patch -

I know Freebird has a post on this somewhere here's a link http://www.venturerider.org/forum/showthread.php?1067-A-list-of-known-problems-on-the-Second-Gen-Venture Patch Worth the membership, glad to help The reason I post under Steven G. is because Don forgot - my password, then my user name, and then my email address, yep it's all Don's fault!

-

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I swapped mine Like Freebird is suggesting. Can be a bit time consuming but worth the effort! I relocated mine to the radio compartment on a tail. I may of posted it on the site if you want to search. Patch -

I’ll post a thread on what I’ve found, but here is what I believe is the best option. Race Tech: To deal with the dive problem Gold Valve Emulator with potential for tuning. In some cases this may be all that your ride needs? Gold Valve Emulator # FEGVS 3801 $170.00 Set Bushings inner # FMBI 40201P $24.00 Set Outer # FMBO 40122P $60.00 Set Copper washers # HMWC 1015 $5.00 ea. Oil seals # FKOS 40P $30.00 Set Dust seals # FKDS 40P $30.00 Set Springs 200lb rider .95 #FRSPS 3234 $130.00 Set The spring rating is .80-.85-.90-.95-1.0 KG per MM. Preload is 25MM or 1” below end cap Recommend oil with Valve Emulator 15W In all cases the outer/lower tubes must be in good order. If minimum ware is visual I would increase W This link to their Venture page. Thier phone number is (951 279 6655) http://www.racetech.com/ProductSearch/12/Yamaha/XVZ1300%20Venture/1987-91 Patch

-

CLASS System ON while engine is running

Patch replied to rrod1393's topic in Venture and Venture Royale Tech Talk ('83 - '93)

If I may make a couple of suggestions to you The coolant leak to me- I would if you haven't do a long soak flush. May as well deal with all those now. Likely when you inspect the leak you'll find some corrosion, well there will be more hidden. After rinsing I would add 2/3 a can of Bar's Leak with pump lubricant, which must be added to through the rad not the overflow! Then I would based again on experience go through every plug connect you can find and there are many; clean and grease each connections. You'll find some that won't pull apart, don't risk breaking those soak them with a penetrant oil! Every so often when you can measure resistance either to the frame or end to end. It will give you an idea of harness condition! The slave will likely require a good cleaning in a bowl and check for pitting, if I recall there are o-rings you can replace just mention to the "o-ring" shop that they sit in hydraulic fluid so they offer up the right compound off their shelves. If I haven't mixed up my bikes slaves? Patch -

Well its all part of the learning curve! I've not been a fan of check the floats in that manner, but is a quick way if you are looking for a particular problem. Key on!

-

"So I just went out and checked how the lower cowlings attach to the bike and they do cover the air intakes on the air filters. Not having them attached would act like a ram air induction. Not sure what effect that would have on the engine but it may be disruptive. I will put them on tomorrow and give it another run. Let you know how it goes." So you were right kind of, you were running out of gas compared to the throttle plate position. If you have experience with say Holly’s or slide carbs you have just experienced Constant Velocity and its venturi process. The CV needs a constant velocity and the tuned balance that the air box provides. So because you in effect unbalanced the air stream pressure, the venturi was incapable of opening the mains. This is why I was asking if you could feel vacuum at the diaphragm/ which is a vacuum actuated piston that pulls the main tapered needle up the main jet. All is well that ends well;)

-

"Air filter ( the whole air box needs proper integrity)" YOU ARE FIRED!

-

Stupid Gas Gauge

Patch replied to SpencerPJ's topic in Venture and Venture Royale Tech Talk ('83 - '93)

I saw a complete 83 dash on ebay today. -

Yep it is the top of the pinion gear. That nut hold the pinion to the coupling gear keeping both in place.

- 6 replies

-

- check oil condition

- final drive

-

(and 1 more)

Tagged with:

-

and the air flow setup is all together, nothing left out? So lets follow the trouble shooting guide checking off one thing at a time as you move through it, unless someone has better input.. When your ready

-

I'll take a look

-

here, you likely have a manual but so w are on the same page start at 6-11 http://www.werder.ee/Manual/XVZ1300.pdf Rule each one out starting with the position sensor

-

You could check pump volume. When you say it runs well in 1st and second, it rpm and throttle position that matters right. Remember mine is a 91, and I'm not sure what yours is, I checked your profile? Are you running stock setup?

-

just taking a quick look and found this, you may have allready read.. http://www.venturerider.org/forum/showthread.php?24246-Set-the-Float-Levels-on-QuickSilver