-

Posts

1,123 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Store

Posts posted by dna9656

-

-

Ok, this HAS to be solved.

I'm so pissed about having to plunk down $130 for a OEM Dunlop (included mounting & balancing) and looking at limited miles. Yet others (Wingers) have solved this issue with glowing reports. I drive the PISS out of my bike and I want things to last. It's time to solve this ETERNAL question because there's us in here that just damn well aren't going to give up our first gen machines unless pried out of our dead hands OR lottery happens.

That being said, one person posted a size on Darksiders for the 89VR (which I have) but NEVER posted if it's a confirm working fit or not. I mean, COME ON!!!! We all know that DS'ing 2nd gens work...and just for the plain poop of it I want to know.

One guy in this tread talked about someone had done it but failed to discuss the size of the tire only to say that the bead was off????

So, I'm planning to get my expensive metric calipers out since I've got the ENTIRE a$$ end of my bike dismantled and I'm going to take pictures and start running numbers to start tracking this down. I want to solve this. Right now I'm just stuck with this bike. I've never changed a tire before and don't have the equipment at home, but I've told my wife I'm pissed about this after what just happened to me (I'll post a pic) and you'll understand why I'm motivated to solve this.

You can get a manually operated tire changing machines on Amazon.com and you'll "make money" (the machines will pay for themselves the first time you change the second tire) the first time you change 2 tires. Harbor Freight has a M/C tire balancer that works, it'll pay for itself after 2 tires as well maybe 4 tires. This is when you can change your own tires you can now spend what you paid some one else to do on better tires or more beer!

-

What could have killed me...https://uploads.tapatalk-cdn.com/20190522/7f48ea77b9869007a72dc36faec12479.jpg

Sent from my SM-G950U using Tapatalk

Sure justification for following the owner's manual concerning inspectying your bike before each ride. If that were a car's tire I'd say you have bad shocks. That would be a severe case of cupping. CT? Circuit Tester? Cannibals Tanks? OH CAR TIRES! Car tires are no way designed to have their side walls on the road as are MC tires. I don't know what car tire you could use on a standard Venture wheel, maybe a Model A tire or some front tires off a Dragster car. Dang bro! inspect them tires!

-

Awesome Doug !!! Looking forward to seeing them.

Somebody please tell me I don't have to take apart the fairing to get the carbs out ? To my surprise it took a crowbar to gently lift them off the boots. Those throttle cables are now 'In the way ". Perhaps if I take apart the twist grip.... LOL, putting this back together will be a b****. ! It has to be done. The slides are covered with foam particles from the degraded air cleaner seal, mixed with oil in a kind of paste. The pilot air orifices also have plenty of goo. What a mess. Perhaps if I re-installed the carbs with some sort of zipper...

I think Freebird is going to move this to a new post as it deals with carbs and not exhaust pipes but anyway.

When you re-assemble the 4 separate carbs to create ONE unit of carbs place all the carbs on a FLAT surface THEN connect the carbs together in to one unit. This way the bottom of the carbs will all be in the same geographic plane; like the intakes are. It will be easier to install the unit of 4 carbs this way. You have to re-install them the same way you took them out.

-

Here are the only pics I have of those parts:

These parts were used on all First Gen Venture rear suspension links. Perhaps you will find some serviceable ones from your other bikes?

Not my first choice as i have to lift the bike, but it seems that's what I'm going to have to do....

-

So the new seal arrived Friday (last) but we signed for a house, had a daughter get married, attened 2 wedding connected dinners, traveled to the ends of the world and we're beat.

I got the old seal off with a knife, the new seal has a band of metal on it, so it presses in place, I saw no such band of metal on the old one so maybe it was bonded. In any event here it is... comments welcome.

I thought it fit right next to the gear but it doesn't. I looked at the pics posted here and the positioning looks good, I test fit the saft to the final drive gear and it is where it belongs. So all that remails is installation. Waiting on other parts now.

-

I will be posting pics from my (5 bikes) parts bikes later today.

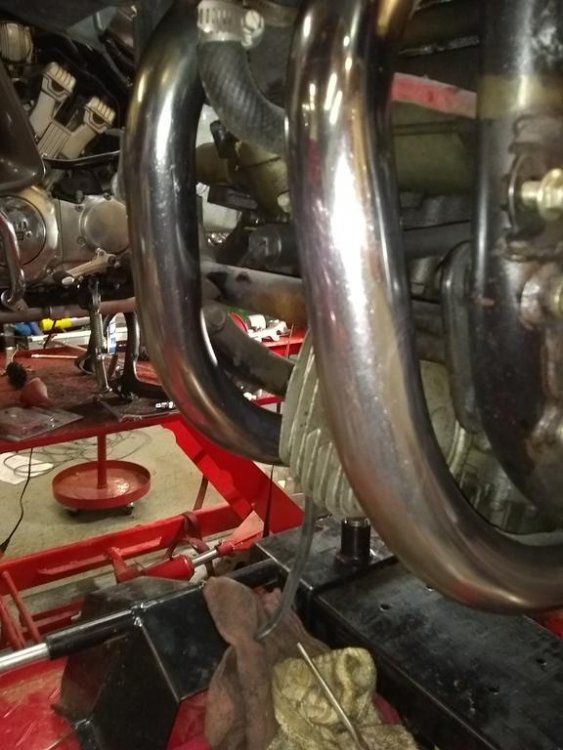

These pics are from the same bike, it's on the H/F lift and (right now) the only bike I can gets parts off of as the other 2 in the garage one is a parts bike and it's jammed in the corner with a bunch of crap in front of it.

I didin't see any rash, like it bottomed out, I did notice a little pin prick rust.

-

I will be posting pics from my (5 bikes) parts bikes later today.

-

Was one of those pics labeled with the word "deferential"?

Now I'm really confused!!

It's NOT differential as there is only ONE WHEEL. Yamaha calls it a "Final Drive Gear".

You don't need a differential when there is only one wheel. Yes, it is a ring and pinion (like a diff uses) buy there re no spider gears, posi or other in there.

-

The gear teeth look near perfect to me, Doug. Maybe even a touch better than my '93 driveshaft (41K miles).

When I removed the driveshaft from the final drive and then tipped the final drive upward (i.e. pointed the opening downward), gear oil poured out of the oil passages. The entire capacity drained out of the final drive onto a piece of cardboard in just a couple hours. That, anyway, is how I confirmed my oil passages were clear.

That's a heck of a way to find out they are open but then if they weren't you'd know right away anyway....

-

I'm glad this is still going. I cant seem to get my silly ideas out of my head.

The cargo I wanted to pull has a dry wt of ~220 lbs, and I figured a custom aluminum trailer made just for the item and the item together would be wt prohibitive. Off the top of my head I would be at 300+ lbs total wt, but it would be relatively flat with low CG. I'm not thinking about a multipurpose trailer, rather a trailer designed and fabricated by me specifically for my 250. My dirt bike weighs about what I do after a robust meal, so how much more wt for a purpose built trailer remains to be seen but I dont think 100lbs would be a bad guess.

The idea I have drafted would take a small dirt bike which would be rolled up longitudinally onto a hinged rail on the extreme right side of the trailer, then fastened to a guide, laid down/locked in an almost flat 10-15 deg angle. I'm a 2 stroke guy so laying them down really doesn't have any apparent ill effect as if it had a crank full of petro, and the extra wt.

I googled before posting this response, and I found this on another site which I am a member. I would not be going upright as pictured. This is the first pic of pulling a bike with a bike I have seen.

Does dark siding effect trailer pulling, I would assume it would be favorable if pulling some wt?

https://advrider.com/f/threads/bike-trailer-towing-a-bike-with-a-bike.213034/

You want to trailer with a 250cc bike? I wouldn't, the bike is too light, the tail is going to wag the dog. Just IMHO.

-

https://www.venturerider.org/forum/attachment.php?attachmentid=114842

Well... I see where you are going here... I have found that if me and the wife run in full nekked cowpuc mode that we might make weight limit. If we wear a pair of socks or have anything in the luggage or tow a trailer... we are waaayyyyy over GVWR as rated by Yamaha. The tires however, will carry 1700 lbs combined. This condition is not unique to the RSV. All tour bikes have around 450 pounds plus/minus capacity and all of them say NO trailer towing. I am assuming that A Gen 1 has about the same carrying capacity. Is there a sticker on your bike that says your weight limit?

A tip: 100 pounds on the pillion equals 200 pounds in a trailer as far as "feel", stopping, steering. You will not want more than 400 lbs gross behind you in a trailer.

But so far as I know we're talking about Ventures and venture Royale, not Royal Star Ventures ;maybe this ia a WAY different bike, maybe it isn't and maybe it makes no difference, I really and honestly don't know. I do know that tires for the Ventures (83 to 93) use the same tires but there are different load ratings amongst the choices to make, the stronger the tire the more money you spend. Were I to tow I think is would be wise to use the strongest rear tire (at least the rear) available.

-

This is one of 2 reasons tires have weight capacity, you can get tires that fit our bikes but you have to watch the load (weight) limit on the tire, especially if you're going to tow! This where I get confused, I have a hitch on my bike, I like the option it gives me, but I need a recommendation for a weight limit; Marcal's comment is a very big help to me as it gives me an idea of how to figure out my enigma!

-

That driveshaft looks near new.

As Rick says, you should consider replacing the oil seal. Although some have removed the driveshaft from the final drive and reinserted it without damage to the oil seal, others have damaged the oil seal while reinserting it, so it is a crap shoot whether you will get lucky. Whether you replace the oil seal with new or reuse it, lightly lube the periphery of the seal with gear lube before inserting into the final drive. The driveshaft simply slides into the final drive housing and is held there by the friction of the oil seal. Clean the inner part of the final drive housing where the oil seal will mate of potentially damaging debris.

Before reinserting the driveshaft, inspect the inside of the coupling, ensuring that someone has not mistakenly greased the coupling and or the big end of the driveshaft and excess grease has blocked the gear lube ports with grease.

Also, before inserting the driveshaft into the final drive, ensure that the compression spring is still attached to the pinion shaft.

The seal now in place is on so tightly ON I wonder if it's bonded (glued) in place. I know I CAN remove it one way or another but I will get the new seal before doing so. Thanks for the reminder to be sure to clean out the oil holes inside the "cup".

Is there a way to do an ops check on those gear lube ports you mention; like filling the drive with lube and positioning it as it were mounted on the bike and see if the gear lube weeps through the holes? At first I thought about lightly greasing the teeth but I think I'll just cover them in lube and install it. As I rtecall cleaning the cup on the final drive gear was a lot harder to do than it should have been making me think it was greased (well) but the person doing the work didn't know much about THESE bikes or bikes in general; you all will remember the pics of the inside of the forks I posted showed that the forks were not re-assembled correctly. I have found other signs of oddly performed maintenance.

Thanks a LOT!

-

It looks good to me and I wouldnt be concerned about it. They seal is on the correct end as the book isnt also the most accurate on some of the diagrams. I would replace it with a new one as it does keep the gear lube in rear end. I would also grease the spines on the other end before you slide it back into the u-joint yoke.

Hope that helps.

Rick F.

Thanks Rick!

-

So here are some pics of my 88 drive shaft. I can see the phonograph finish on the crown of the teeth on the small side. BOTH sides look pretty good to me. Your opinion(s) would be welcome.

What is the proceedure to re-install; it's been a few months since i took it all apart.... The seal shown in the bottom picture... is that the proper seal? The parts book shows a seal at the OTHER end of the drive shaft... clarification please!?

-

Thanks! I have these pics, they are SIMILAR to the other 2 part numbers. I am looking to give the bearing company EXACT pictures of what I seek. The dimensions I gave them (when running an internet search result are oil seals similar to those used on the front wheel of our motorcycle. This type of seal won't work. See below for my pics of what I removed from my 88. Below are pictures the 3 different part numbers; of cover, dust, cover, thrust1, cover, dust 2. I have thoroughly researched this issue.

Item 18 on the parts list for the 1988 year model bikes is PART NUMBER 26H-22128-00-00; "COVER, THRUST" the assembly requires 2 each, that's about $34.00 +shipping.

Item 34 on the parts list for the 1988 year model bikes is PART NUMBER 26H-2217H-00-00 "COVER, DUST" PART NUMBER No price at all on the parts list the assembly requires 4 each,

Item 36 on the parts list for the 1988 year model bikes is PART NUMBER 26H-22129-00-00 "COVER, thrust 2" @ $14.39 + shipping and 4 each are required .

-

Would like a picture (both sides if possible) of these parts; THANKS in advance!

For 1986 and up bikes specifically an '88.

-

You could try to contact Dustyroads, (member here), he has an 85 all torn apart and wanted to leave it in my driveway

Is there a way to find him? i can't find a member search....

-

Or try:

Or maybe just make one from a plastic bottle cap with a rubber insert. There is little to no pressure on these so it's not like they will be under stress and crack I don't think.

Thinking about doing some thing like that!.

-

I gather you're referring to parts 22, 23, 24 in the following? Last year I tried to rebuild the swingarm components on my '84 - washers, bushings, etc. The parts are hard to find and expensive. Someone on the list here may know of other aftermarket substitutes.

https://www.venturerider.org/forum/attachment.php?attachmentid=114693

Yes, those are the parts. Some are available on line from the New Old Stock sellers, however the least expensive I have found is $16.?? + shipping of $8.??.

As I need all of these for the 88 (I believe there are 4 of each part number shown in the parts book for the '88) I'm not spending $64.00 for what is essentially a a washer with some rubber bound to it. I think I can do just as well with some neoprene rubber (cut out a ring and bond it to the washer) and RTV rubber for about $5.00. In other words those prices are exorbitant. Those sellers will have those parts a LONG time.

-

So, I have had my post on dust covers and thrust washers up for a while now and Cowpuc is the only person to respond and he's defiantly not sure about what I'm referring to.

These are the washers with the seals on them that go on the Arm and Arm 1 at the bottom of the spring/shock thingy, right next to the whatchamacallit.

ONE of these is available at usury prices on the internet, SOMEBODY here has run into this before, I need to know what o use instead of the Yamaha parts, anybody?

-

IMHO they could if the caliper is attached to the bracket and the pads are out far enough that they are keeping the caliper from sliding over the rotor while your trying to slide the bracket down to like it up with the axle... iWith the pistons compressed fully so the pads are wide open one should fairly easily be able to slide the caliper over the rotor while it is still attached to the bracket and then line up the bracket, slide the axle in and then put the forward bolt with the dowel end on it into the bracket...

I can't speak for Duey but I got a gut feeling that that is what he was talking about..

Caliper, There are no pads in the caliper, the caliper is tied off, out of the way, caliper bracket, and wheel are all removed from the bike. That's why the caliper is not the issue...

It's been a long time since I have had a bike apart; but I think the caliper bracket has to be in place before the wheel is installed because there is no room to get the caliper bracket in once the wheel is installed so that is what is going on in more detail...

The first pic is how I started the install of the caliper bracket section of job. Note; no tire/wheel so the caliper proper and it's associated parts aren't part of the picture literally!

In the next pic you can see the paint on the caliper bracket nub on the long side of the Swing Arm; note how much bigger the nub is vs. the '83 to 85 models. The bracket can be installed only one way because like the Mark 1 the holes on each end are different sizes. So I removed the paint and the bracket fit, so I applied a little grease to the bracket and installed it.

I appreciate the membership for all the help and guidance you give me and keeping me straight! CRS is real!

-

When installed on the wheel correctly, the brake rotor rim should be offset toward the swingarm, i.e. dish out.

Thanks Kevin! I didn't want to learn that the hard way. I shoulda took a pic!

-

To All;

Thanks for your responses!

The arm is installed. Due to bad lighting I could not see the primer and paint I on the nub that

I neglected to mask off prior to painting. After removing the primer and paint the BRACKET slid on just like it's supposed to!

All is well now Thanks!

rear wheel bearing/seal order

in Venture and Venture Royale Tech Talk ('83 - '93)

Posted

Do you have the manual? If so follow the instructions there in, (if you have the proper and correct tools) or take the wheel to a dealer or a knowledgeable motorcycle mechanic. I have 1983 wheels on hand.

Please keep me informed.